There is a mainstream belief that a 5-year business plan is a prerequisite to launching a startup; that an entrepreneur must forecast income, profits, cash flow, services, products, risks and what else, before bothering to raise money. Once an entrepreneur is equipped with a solid business plan and minimal risks, only then can they approach investors and start developing their product. They spend hours creating a master plan and product features, only to receive customer feedback post-launch, and realize the futility of most of these features a few months down the line.

The Business Plan is a rigid approach in today’s ever-changing world. It rarely survives first contact with a customer and is fictive in nature, with made-up predictions that seldom turn out to be true. While businesses execute a business model, startups try to create one. Visionaries with a goal in mind, entrepreneurs move from failure to failure while adapting, iterating and improving based on customer feedback. Launching a startup is a bit of a hit-or-miss process – many startups have failed, many probably will, but nonetheless, there does exist a popular way used nowadays to create products and help make the “starting of a company” less risky; the magic methodology is called the “lean startup” (LSM).

A serial entrepreneur, Eric Reis, co-founded IMVU, an online social network via which he experimented and developed a methodical approach to launching companies. On a mission to save entrepreneurs, he published the “Lean Startup” in 2011, saying that “startup success is not a consequence of good genes or being in the right place at the right time. Success can be engineered by following the right process, which means it can be learned, which means it can be taught.”

The formula leans on experimentation rather than elaborate planning; on customer feedback instead of guessing; and iterative over traditional up-front design. The LSM framework consists of 2 elements:

- The LSM Core – which is all about measurable outcomes that can be acted upon in some logical way; “increasing downloads by 15%” for example, as opposed to “increasing downloads” makes it easier to operate in an outcome-based manner.

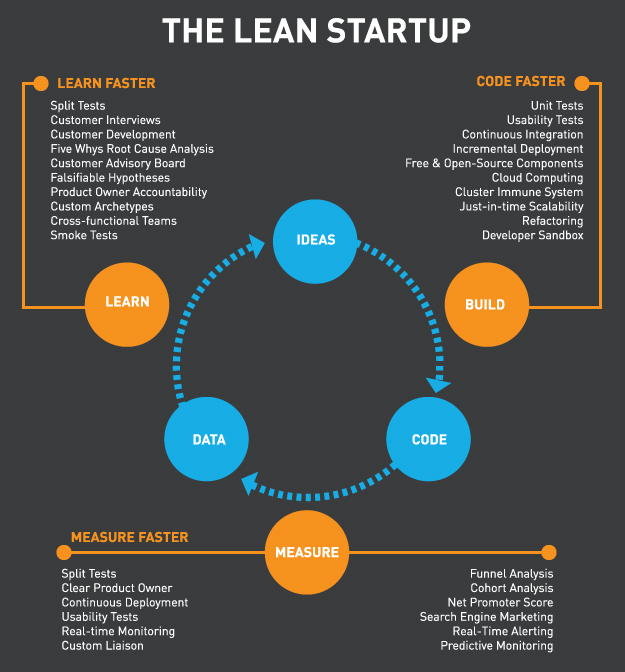

- The LSM Cycle – As Reis eloquently puts it: “A startup is a catalyst to go from an idea to a product or service.” As customers interact with these products and services, which are in fact experiments, they generate feedback and data; both qualitative and quantitative. These experiments follow a three-step process: build, measure, learn.

The idea is to go through the loop as fast as possible to test a hypothesis.

Our goal is to learn important insights about customers, and so we must look into how much of our effort actually contributes to that learning. What efforts are actually creating value and which are wasteful? This question is at the core of the lean-manufacturing revolution; lean companies such as Toyota have learnt to see waste and eliminate it, which has proven very beneficial as they dominate the auto industry. Lean thinking is about providing benefit to the customer, while defining everything else as waste.

When speaking of startups, who the customer is and what they find valuable are not as straightforward; it is therefore crucial to experiment in order that we may learn and define customer value, which will help us build a sustainable business in the long run.

To give a brief overview of the lean startup methodology process and the aspects involved:

1. Build, Measure, Learn

Find the fastest way to iterate in order to find what customers really want.

2. The Minimal Viable Product (MVP)

Build only the amount of product needed to iterate

3. Validated Learning

Learn via data that does not allow for vanity metrics such as Facebook likes (that do not say much about how a company is doing.)

4. Innovation Accounting

Establish the baseline with an MVP test to see potential customer interest; make one change that can be tested and improve upon it; move up the baseline towards the ideal goal.

5. The Pivot

Change one of the fundamental hypotheses we started with, which may push us to let go of a product we have spent much energy developing.

6. Small Batches

Work the process as one batch in order to spot an error immediately.

7. The Andon Cord

Spot a problem immediately and stop everything if necessary, until addressed. This was used by Toyota, where an employee could call a halt to the system during the production line.

8. Continuous Deployment

Constant update of production systems.

9. Kanban

Create a story in the product development process and harness the power of visual information, such as by using sticky notes on a whiteboard. This is another technique borrowed from the lean manufacturing world.

10. The 5 Whys

Using this technique allows us to get closer to the root cause of a problem. Eric Ries believes that most discovered problems tend to stem from lack of appropriate training – while they may seem to be technical issues, or individual mistakes on the surface.

And to try to conclude for the sake of this article, LSM is a method for creating and sustaining innovation while helping answer 2 questions:

- Should we build this new product or service?

- How can we increase success?

When we know the answers, we can reduce unnecessary failures and instead, focus our time and money on ideas that have promise.

Latest Business

Intelligence Report